infrastructure

Safe infrastructure for NewSpace

Plastron was established to make the space sector safer – by design. Our flagship product is the Plastron payload processing facility, a modular state-of-the-art structure designed for all types of hazardous activities involving spacecraft. Our facility meets current European space standards for spacecraft cleanrooms, providing a highly efficient ISO8, ATEX z1 explosive atmosphere working environment for:

The Plastron is a stand-alone facility, employing a high-quality supply-chain to ensure all facility systems are fit-for-purpose. Drawing on our expertise in hazardous engineering and cleanroom workflows, the Plastron helps to optimise processing timelines and with its custom-designed HVAC air system, consumes less than 50% power of conventional cleanroom HVAC systems.

Below are examples for how the modular design is applied across upstream space hardware processes.

A modular, state-of-the-art facility for hazardous handling of space hardware, meeting all requirements for assembly, test, transportation and launch check-out/encapsulation.

The design meets – and in places – exceeds current operating standards for spacecraft facilities as defined by the European Space Agency.

A cost-effective concept applicable for all phases of upstream space hardware development, designed for agile NewSpace delivery working practices. Self-contained with full operational capabilities assured by:

- ATEX z1 working environment

- ISO8 – ISO6 with temperature and relative humidity

- Blast protection up to TNT equivalent of 2.5Kg

- Earthed facility with lightning discharge protection

- Secure data and WiFi network

- Standard power, gas and liquid interfaces

- Smoke & toxic gas sensor alarm system

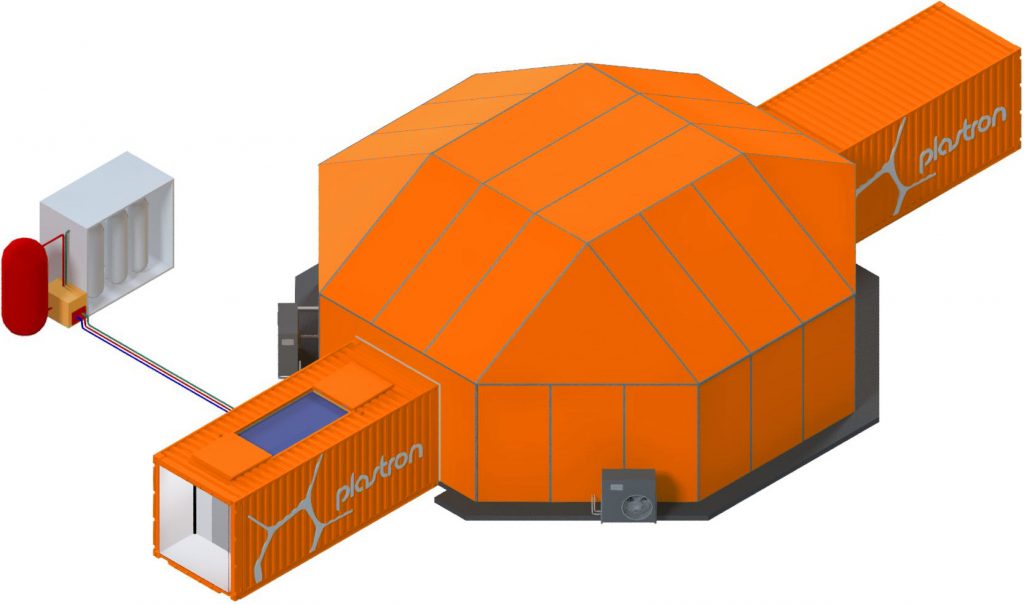

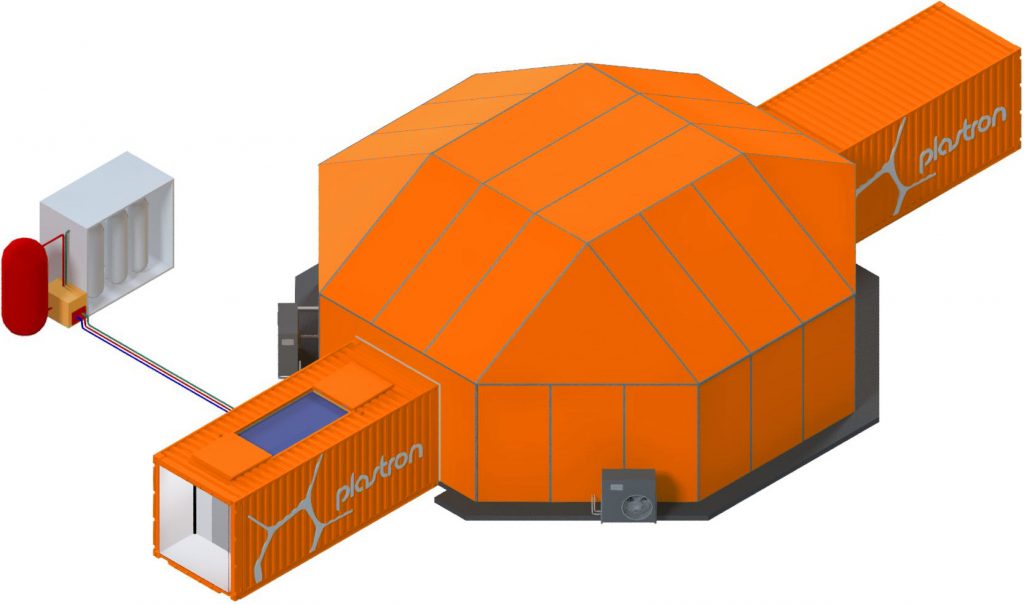

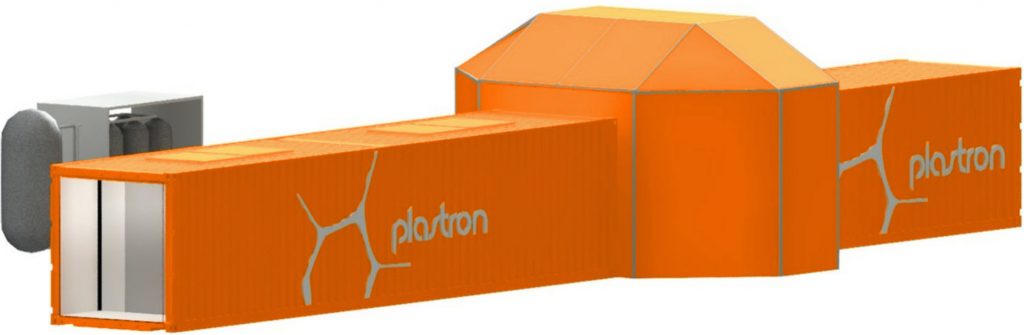

The design is modular, which means each unit can be adapted to fit specific purposes and combine together to provide a dedicated, fit-for-purpose facility. The core modules are, from left to right:

- Hazard bay and hardware airlock

- Central hardware handling environment

- Personnel garment room

The standard facility provides a 75 sqm work space, with a working clearance of 4.5m. Fully compliant with the needs of smallSats up to 1,000 Kg, including protection against uncontrolled toxic chemical and high pressure releases.

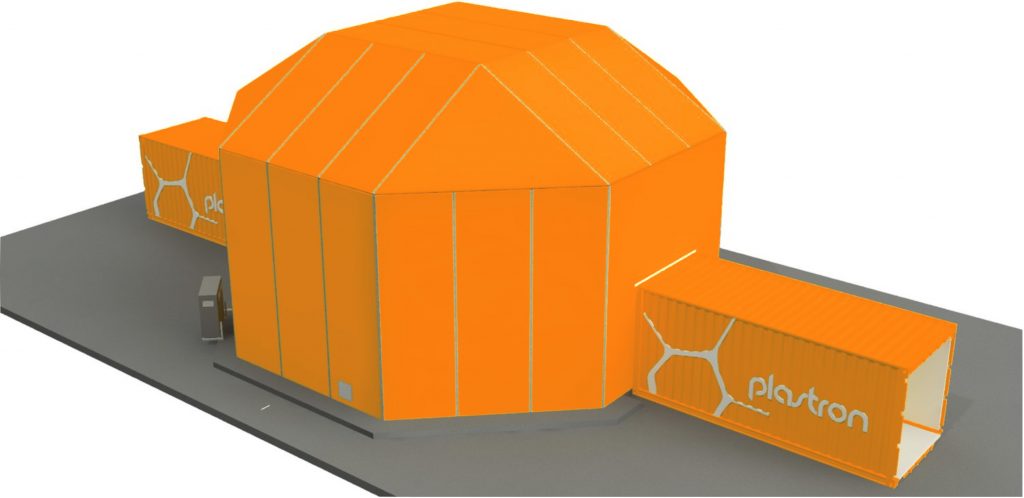

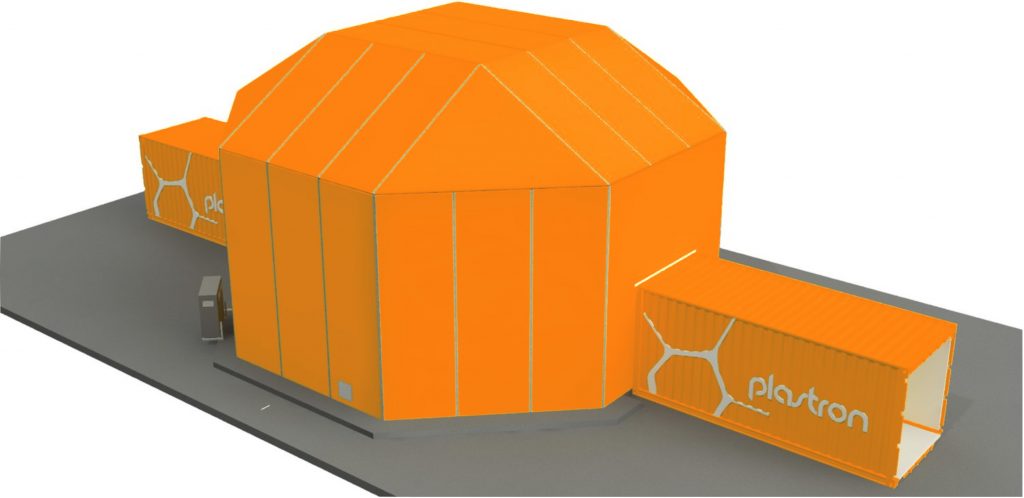

The Plastron High Hat

- 75 sqm ATEX z1 workspace

- Working height increased from 4.5 m to 6 m

- 12 sqm hazardous processing workspace

- Dynamic ISO8 environment

- Personnel airlock

- Standalone facility

The Micro Launcher Facility

- 10 sqm ATEX z1 interface

- 20 sqm hazardous processing workspace

- Dynamic ISO8 environment

- Personnel airlock

- Standalone facility

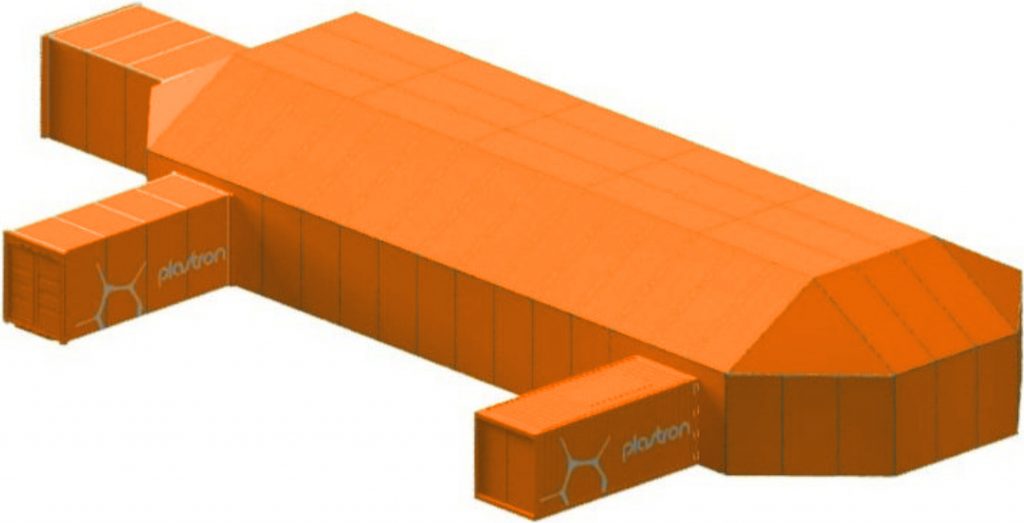

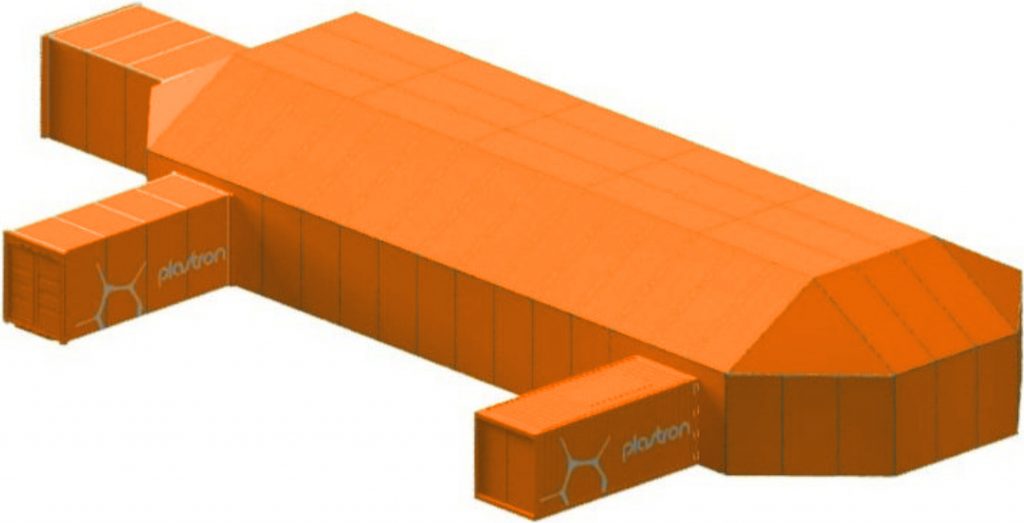

The Small Launcher Village

- 300 sqm ATEX z1 workspace

- 12 sqm hazardous processing workspace

- Dynamic ISO8 environment

- Personnel airlock

- Standalone facility

The Plastron Transporter

- 12 sqm contained hazardous storage

- Dynamic ISO8 environment

- Self-contained facility

- DVLC qualified transport

Our approach represents a radical departure from well-established norms which have underpinned the space industry for the past 30+ years. And whilst it is radical, it is not about risk-taking; we ensure our facilities go beyond convention to provide state-of-the-art smallSat cleanrooms; and our design approach is focused on both ecological impact mitigation, orbit debris avoidance as well as operational safety. Please use the contact form below to learn more about the Plastron facility.